What is Electrical Safety Testing

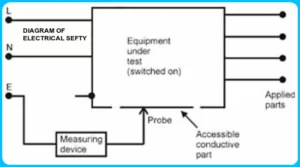

Electrical safety testing is performed to evaluate the potential damage caused by electric shock while using the equipment. Or rather, electrical testing is an important process.

It is a periodic inspection report that shows whether a circuit or electrical appliance is being overloaded, any potential electric shock hazards and fire hazards from its installation

The evaluation of a product for electrical safety typically includes the following tests:

High voltage test – Measures the ability of an electrical product to withstand the high voltage applied between an appliance’s electrical circuit and ground.

Leakage Current Test – It evaluates whether the current flowing between the AC source and ground does not exceed a specified limit.

Insulation Resistance Testing – Calibrates the quality of the electrical insulation used leading to longer life.

Ground Continuity Testing – This involves ensuring that a clear path is available between all exposed metal surfaces and the power system ground.

Article About:- Health & fitness

Article About:- Medical Technology

Article About:- Amazon Product Review

What is a Medical Device Applied Part?

This Applied Parts (AP) is a part of medical electrical equipment that is in physical contact with a patient to perform its function as required for medical electrical equipment or medical electrical systems in use.

These are classified in three ways: B (Body), BF (Body Floating), and CF (Cardiac Floating) depending on the nature of the medical device used and the type of contact.

What is a Type B medical device?

There is a classification of type B (body), and is used for parts that are not normally conductive and can be released immediately from the patient. Examples would be LED operating lighting, medical lasers, MRI body scanners, hospital beds and phototherapy equipment.

What are the standards in electrical safety testing

IEC 60601 and IEC 62353

The resistance of the appliance’s power cord is 0.2ohms. should be less than IEC 60364 has been established by engineering experts from all countries of the world comparing their experience to international level.

What are the benefits of electrical safety

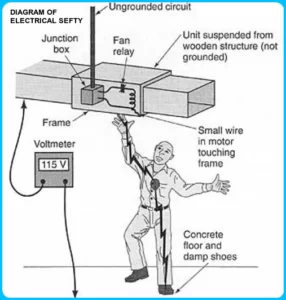

Internal electrical problems such as bad or deteriorating wiring, as well as short circuit problems, can both easily lead to a fire. State of the art plumbing, air conditioning and electric will be able to easily test your home for any danger of shorting or any wiring problems that could lead to a fire.

What are the Different Classes of Medical Devices

There are mainly 3 classes of medical devices:

Class I devices are low-risk devices. Examples include bandages, handheld surgical instruments, and non-electric wheelchairs.

Class II devices are intermediate-risk devices. ,

Class III devices are high-risk devices that are very important for maintaining health or life.

Class I = low risk.

Class IM (measuring instrument) = low risk.

Class is (sterile equipment) = low risk.

Class IIa = Moderate risk.

Class IIb = Moderate to high risk.

Class III = high risk.

What are the electrical safety of medical equipment?

IEC 60601 is a series of technical standards for the safety and effectiveness of medical electrical equipment. The primary standard governing medical device design is formally known as IEC 60601-1 – General Requirements for Medical Electrical Equipment Basic Safety and Required Performance.

1. Fly kites away from power lines. Lightning finds the fastest path on the ground (conducting), which can be down the kite’s strings if it touches an active power line.

2. Do not fly the drone near power lines. If it hits a power line, they can cause a power outage.

3. Keep away from electrical substations.

4. Never play on transformers. Underground pad mount transformers must be clearly marked with a safety warning.

5. Do not climb trees near power lines. If the branches touch the wires, the tree can get energy.

6. Electricity and water do not match. Keep all electrical appliances away from water.

7. Never move the electrical wire against the wall. Pulling the cord can damage the appliance, plug, or outlet.

8. Electrical outlets are for plugs only.

9. Avoid using damaged cords. Torn or worn wires can be a safety hazard.

10. Electrical wires should be kept out of the way. Keep all cords away from main traffic areas where people may travel.

What is a security analyzer used for?

An electrical safety analyzer is an instrument used to perform various electrical safety tests, including ground continuity tests, insulation tests, high voltage tests and line leakage tests, to check whether the equipment under test meets the electrical safety requirements. is in compliance.

What is the allowable leakage current?

To provide a margin of safety for equipment, regulatory agencies typically require that a product exhibit a line voltage leakage current of less than 0.5mA.

With some products equipped with 3-prong plugs and warning stickers, the permissible leakage current can be as high as 0.75mA, but the typical limit is 0.5mA.

What is a functional test in electrics?

An electrical function test (FCT) – often also called an end of line test (EOL test) – is a test in the electronic manufacturing service industry that tests the functional performance of an assembly.

What is meant by functional testing?

Functional testing is a type of testing that attempts to establish whether each application feature works as per the software requirements. Each function is compared to determine whether its output is in line with the end user’s expectations.

What are functional tests?

The above use-case scenario can be tested through a variety of functional testing techniques.

End-user based / system test. Tests the system to find out if all the components are working perfectly in combination.

- Equivalence test.

- limit value test.

- Decision based testing.

- ad hoc test.

FAQ

What is the electrical safety testing?

Numerous electrical safety tests are performed under various single fault conditions to ensure that there is no risk even if these circumstances arise in real life. A single fault state is frequently the worst case scenario and will produce the worst outcomes.

What are the 7 electrical tests?

Electrical test of the ground and earth system.

Electrical Insulation Resistance Test.

Electrical Short Circuit Test.

both overloading and electrical faults.

Electrical Test of a Protective Device.

Electrical tests for leakage.

What are the types of electrical testing?

Electrical Testing Types

Testing for continuity.

Testing for Insulation Resistance.

Testing for ground resistance.

Testing the voltage.

Testing for Earth Leaks.

How do you conduct an electrical safety test?

How to Run a Do-It-Yourself Electrical Safety Check Examine the breaker panel. Check the area around your breaker panel and the panel itself.

A GFCI test.

Examine Your Outlets.

Uncovered wiring.

Cord extensions.

Outlets outside.

Check the tightness of your outlets.

Testing the voltage.

What are the three types of electrical test?

UK Electrical Testing Types

Supply test: This gauges the electrical supply’s voltage. The voltage must fall within the range that is suitable for the gadgets and machinery being used.

Circuit test: This gauges the circuit’s overall current flow.

RCD test: This gauges the circuit’s resistance.

What are the 5 types electrical?

There are 5 Main Types of Electric Circuit – Close Circuit, Open Circuit, Short Circuit, Series Circuit and resemblant Circuit. Learn in Detail. There are 5 Main Types of Electric Circuit – Close Circuit, Open Circuit, Short Circuit, Series Circuit and resemblant Circuit.